Page 65 - CARILEC CE Journal CEMAY2021

P. 65

Companies today are increasingly moving towards a sustainable corporate vision aimed at reducing their

environmental impact. Zuccato Energia ORC modules – thanks to their low operating temperatures, represent

an excellent choice to recover waste heat from a wide range of engines and gensets, to which they may be

interfaced safely and easily through a simple hot- or overheated-water loop that ensures efficiency, safety

and simple engineering. This technology permits covering a part or all of the electricity self-consumption

of the factory or industrial plant with consequent economic savings on energy consumption, which can be

reinvested in the company’s core business.

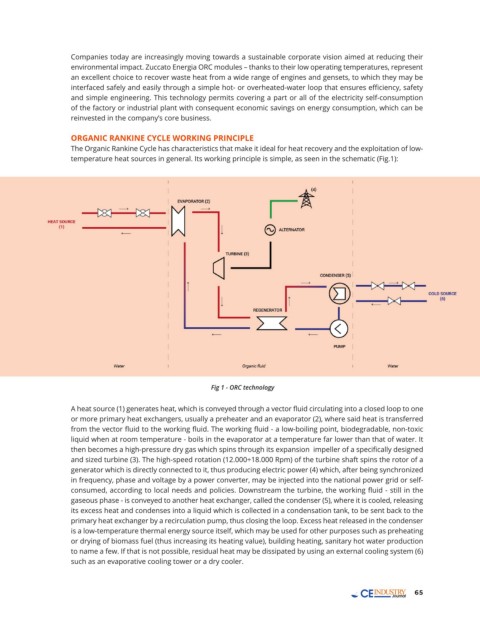

ORGANIC RANKINE CYCLE WORKING PRINCIPLE

The Organic Rankine Cycle has characteristics that make it ideal for heat recovery and the exploitation of low-

temperature heat sources in general. Its working principle is simple, as seen in the schematic (Fig.1):

Fig 1 - ORC technology

A heat source (1) generates heat, which is conveyed through a vector fluid circulating into a closed loop to one

or more primary heat exchangers, usually a preheater and an evaporator (2), where said heat is transferred

from the vector fluid to the working fluid. The working fluid - a low-boiling point, biodegradable, non-toxic

liquid when at room temperature - boils in the evaporator at a temperature far lower than that of water. It

then becomes a high-pressure dry gas which spins through its expansion impeller of a specifically designed

and sized turbine (3). The high-speed rotation (12.000÷18.000 Rpm) of the turbine shaft spins the rotor of a

generator which is directly connected to it, thus producing electric power (4) which, after being synchronized

in frequency, phase and voltage by a power converter, may be injected into the national power grid or self-

consumed, according to local needs and policies. Downstream the turbine, the working fluid - still in the

gaseous phase - is conveyed to another heat exchanger, called the condenser (5), where it is cooled, releasing

its excess heat and condenses into a liquid which is collected in a condensation tank, to be sent back to the

primary heat exchanger by a recirculation pump, thus closing the loop. Excess heat released in the condenser

is a low-temperature thermal energy source itself, which may be used for other purposes such as preheating

or drying of biomass fuel (thus increasing its heating value), building heating, sanitary hot water production

to name a few. If that is not possible, residual heat may be dissipated by using an external cooling system (6)

such as an evaporative cooling tower or a dry cooler.

65