Page 29 - CE_Industral_Journal_2015

P. 29

Figure 9: Electrical testing data after moisture reduction with an online dryer

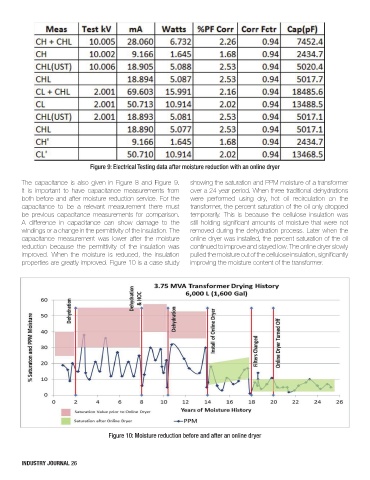

The capacitance is also given in Figure 8 and Figure 9. showing the saturation and PPM moisture of a transformer

It is important to have capacitance measurements from over a 24 year period. When three traditional dehydrations

both before and after moisture reduction service. For the were performed using dry, hot oil recirculation on the

capacitance to be a relevant measurement there must transformer, the percent saturation of the oil only dropped

be previous capacitance measurements for comparison. temporarily. This is because the cellulose insulation was

A difference in capacitance can show damage to the still holding significant amounts of moisture that were not

windings or a change in the permittivity of the insulation. The removed during the dehydration process. Later when the

capacitance measurement was lower after the moisture online dryer was installed, the percent saturation of the oil

reduction because the permittivity of the insulation was continued to improve and stayed low. The online dryer slowly

improved. When the moisture is reduced, the insulation pulled the moisture out of the cellulose insulation, significantly

properties are greatly improved. Figure 10 is a case study improving the moisture content of the transformer.

Figure 10: moisture reduction before and after an online dryer

industry Journal 26