Page 28 - CE_Industral_Journal_2015

P. 28

CASE StUdIES and were also greatly improved from the starting values.

Figure 6 shows a case study of oil testing results preformed

after each pass during oil service. The oil was tested for Figure 7 shows a case study of moisture reduction on a

moisture, acid, and interfacial tension (IFT). A pass is defined very wet transformer using an online dryer. At the beginning

as the total gallons of the transformer cycled through the of treatment, the moisture content (PPM) and the moisture

oil processing equipment one time. In Figure 6 it can be saturation were both high – high enough that even free

seen that, in general, the oil qualities improve after each water was present. Over time, the online dryer lowered the

pass of the hot oil cleaning. After each pass, the water ppm PPM moisture content and the saturation. At the end of the

and the acid should decrease and the IFT should increase. three years, the moisture problem was corrected, and the

When the hot oil cleaning was completed, the dielectric inlet PPM, outlet PPM, oil temperature, and saturation all

breakdown (ASTM D877) and inhibitor content were tested reached equilibrium.

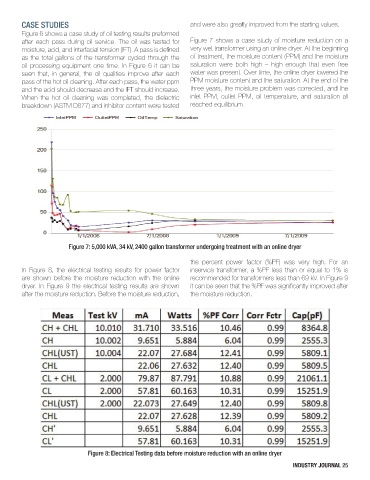

Figure 7: 5,000 kVA, 34 kV, 2400 gallon transformer undergoing treatment with an online dryer

the percent power factor (%PF) was very high. For an

In Figure 8, the electrical testing results for power factor inservice transformer, a %PF less than or equal to 1% is

are shown before the moisture reduction with the online recommended for transformers less than 69 kV. In Figure 9

dryer. In Figure 9 the electrical testing results are shown it can be seen that the %PF was significantly improved after

after the moisture reduction. Before the moisture reduction, the moisture reduction.

Figure 8: Electrical testing data before moisture reduction with an online dryer

industry Journal 25