Page 37 - CARILEC CE Journal CEMAY2021

P. 37

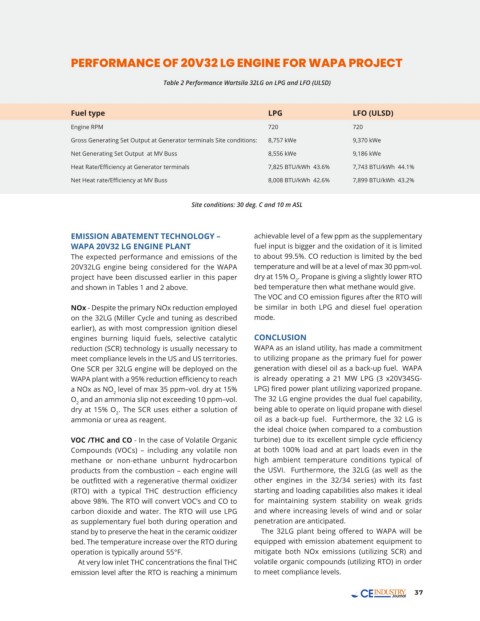

PERFORMANCE OF 20V32 LG ENGINE FOR WAPA PROJECT

Table 2 Performance Wartsila 32LG on LPG and LFO (ULSD)

Fuel type LPG LFO (ULSD)

Engine RPM 720 720

Gross Generating Set Output at Generator terminals Site conditions: 8,757 kWe 9,370 kWe

Net Generating Set Output at MV Buss 8,556 kWe 9,186 kWe

Heat Rate/Efficiency at Generator terminals 7,825 BTU/kWh 43.6% 7,743 BTU/kWh 44.1%

Net Heat rate/Efficiency at MV Buss 8,008 BTU/kWh 42.6% 7,899 BTU/kWh 43.2%

Site conditions: 30 deg. C and 10 m ASL

EMISSION ABATEMENT TECHNOLOGY – achievable level of a few ppm as the supplementary

WAPA 20V32 LG ENGINE PLANT fuel input is bigger and the oxidation of it is limited

The expected performance and emissions of the to about 99.5%. CO reduction is limited by the bed

20V32LG engine being considered for the WAPA temperature and will be at a level of max 30 ppm-vol.

project have been discussed earlier in this paper dry at 15% O . Propane is giving a slightly lower RTO

2

and shown in Tables 1 and 2 above. bed temperature then what methane would give.

The VOC and CO emission figures after the RTO will

NOx - Despite the primary NOx reduction employed be similar in both LPG and diesel fuel operation

on the 32LG (Miller Cycle and tuning as described mode.

earlier), as with most compression ignition diesel

engines burning liquid fuels, selective catalytic CONCLUSION

reduction (SCR) technology is usually necessary to WAPA as an island utility, has made a commitment

meet compliance levels in the US and US territories. to utilizing propane as the primary fuel for power

One SCR per 32LG engine will be deployed on the generation with diesel oil as a back-up fuel. WAPA

WAPA plant with a 95% reduction efficiency to reach is already operating a 21 MW LPG (3 x20V34SG-

a NOx as NO level of max 35 ppm–vol. dry at 15% LPG) fired power plant utilizing vaporized propane.

2

O and an ammonia slip not exceeding 10 ppm–vol. The 32 LG engine provides the dual fuel capability,

2

dry at 15% O . The SCR uses either a solution of being able to operate on liquid propane with diesel

2

ammonia or urea as reagent. oil as a back-up fuel. Furthermore, the 32 LG is

the ideal choice (when compared to a combustion

VOC /THC and CO - In the case of Volatile Organic turbine) due to its excellent simple cycle efficiency

Compounds (VOCs) – including any volatile non at both 100% load and at part loads even in the

methane or non-ethane unburnt hydrocarbon high ambient temperature conditions typical of

products from the combustion – each engine will the USVI. Furthermore, the 32LG (as well as the

be outfitted with a regenerative thermal oxidizer other engines in the 32/34 series) with its fast

(RTO) with a typical THC destruction efficiency starting and loading capabilities also makes it ideal

above 98%. The RTO will convert VOC’s and CO to for maintaining system stability on weak grids

carbon dioxide and water. The RTO will use LPG and where increasing levels of wind and or solar

as supplementary fuel both during operation and penetration are anticipated.

stand by to preserve the heat in the ceramic oxidizer The 32LG plant being offered to WAPA will be

bed. The temperature increase over the RTO during equipped with emission abatement equipment to

operation is typically around 55°F. mitigate both NOx emissions (utilizing SCR) and

At very low inlet THC concentrations the final THC volatile organic compounds (utilizing RTO) in order

emission level after the RTO is reaching a minimum to meet compliance levels.

37